Application

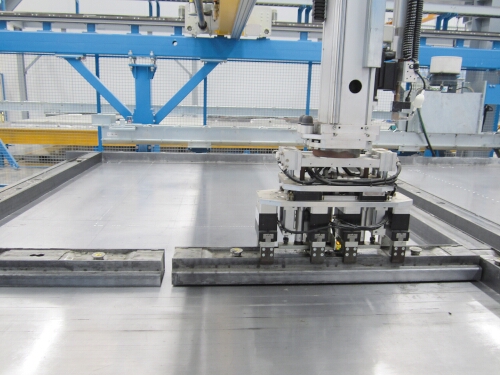

Can be used as a complete system for the production of solid elements from 3'' high as well as for columns, binders, special beams, stationary production as well as for circulation systems with and without siderail robots.

Can be used in recesses which are set by robots.

Especially suitable for

- Circulation systems

- Jobs with siderail robots

- Jobs with a high degree of automation

Highlights

- High-precision laser-cut design

- MSR is configured according to customer requirements

- Handling with lifting beam, crane and robot possible.

- Extendable on request

- Telescopic on request

Features

The following special features distinguish the MSR Modular Siderail System.

If you have any questions about these and other features, please contact us.

Can be manipulated with a crane

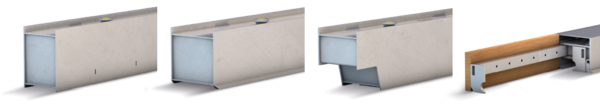

Wooden shuttering skin

Integrated, switchable magnets

Extendable in height

Concretable on both sides

Steel shuttering skin

Profilable according to customer requirements

Suitable for lifting beam

Suitable for robots

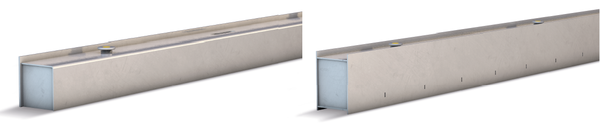

MSR front plate characteristics a) smooth on one or both sides, b) chamfer on top and/or bottom, c) with grouting groove and shear key, d) Profile for slab supports

MSR cover panel characteristics: a) Transport receptacle, gripping knobs, b) Keyhole, receptacle for plug lifting beam, c) Crane attachments, d) Screw connection for upper parts

MSR front face characteristics: a) plain, b) chamfer on top and/or bottom, c) Profile, d) Telescopic for flexible lengths

Accessories

The following components and accessories are available for the MSR. For special solutions please contact us!

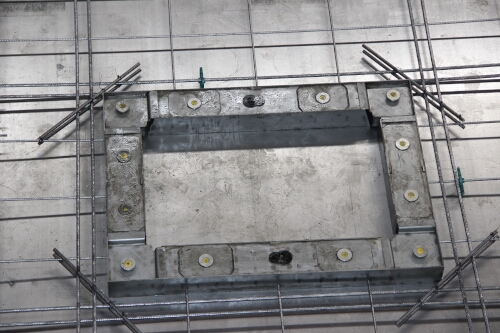

MSR system windows

Robot-capable system window on MSR basis, consisting of SAS siderail in unit length of 17 3/4''. These are set manually or by robot. Intermediate pieces that are shorter than the 17 3/4'' grid are lined with polystyrene. The end pieces of the siderail are closed with a cover plate to guarantee clean edges.

| L (in) | |

|---|---|

| MSR system windows Art. No. On request | 17 3/4 |

System siderail for windows/doors on MSR basis

The sides of the recess are first positioned and then completed with a corner magnet. For stripping, first the corner is removed and then the sides. The corner magnet can be combined with robot- or crane-capable steel siderail as well as with woodclad siderail. The leg siderail can be set by robot. The corner magnet is set and released manually.

| H (in) | |

|---|---|

| System siderail for windows/doors on MSR basis Art. No. On request | 4'' - 15 3/4'' |

Corner magnet

Corner magnet for recesses, including automatic magnet component with a retaining force of approx. 992 lbs.

| Corner magnet Art. No. On request |

Magnetic vinyl for MSR

To cover openings in the siderail's cover panel, such as keyholes, and to protect against the ingress of concrete.

| Dimensions | Material | |

|---|---|---|

| Magnetic vinyl for MSR Art. No. On request | By request | Magnetic vinyl PF 518, magnetised multi-pole on single side |

Cover sheet for MSR

For covering the base during casting

| Cover sheet for MSR Art. No. On request |

Upper parts for MSR

We would be happy to realise different upper parts (double or one-sided versions) for the extendable MSR specifically to your requirements.

| Max. height of the structure = double height of the base | up to max. 8'' | |

|---|---|---|

| Upper parts for MSR Art. No. On request |

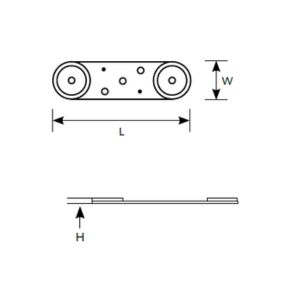

Adapter plate for attaching a wooden front

| H (in) | L (in) | W (in) | |

|---|---|---|---|

| Adapter plate for attaching a wooden front Art. No. 50413 | 1/2 | 5 7/8 | 1 1/2 |

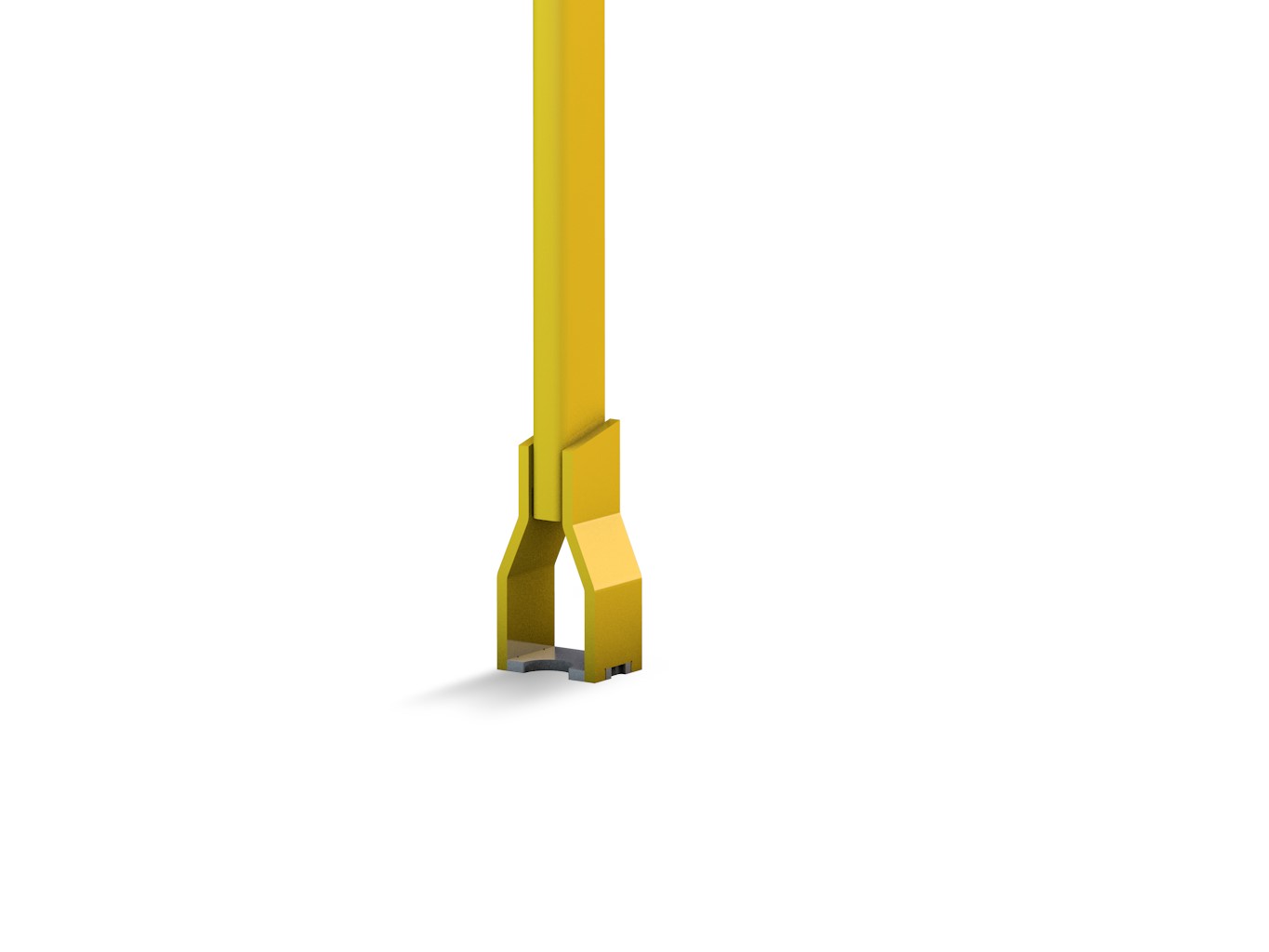

Lifting tool R-Popper-LR for KPB 3000 / 4000

| For | |

|---|---|

| Lifting tool R-Popper-LR for KPB 3000 / 4000 Art. No. 03292 | KPB 3000, KPB 4000 |

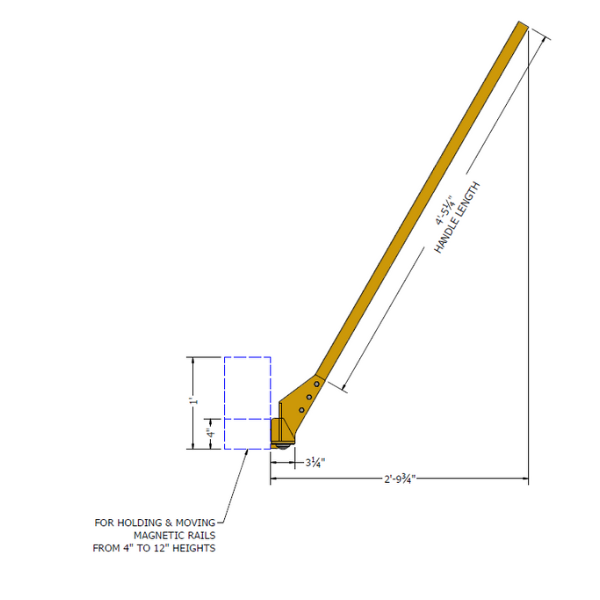

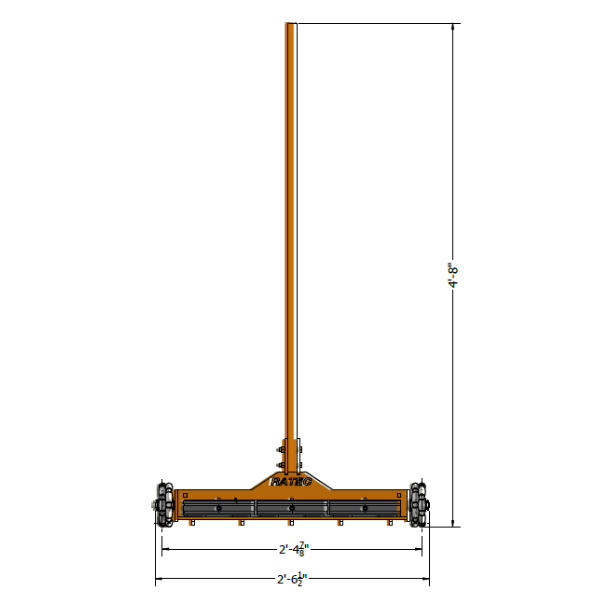

Rail Slider for MSR

A magnetic moving and handling device for your siderail system equipped with three magnets, each with 2000 lb. of holding force. Can hold & move magnetic rails from 4'' to 12'' height No more bending or lifting. Easily slide your rail in place and click. POP, SLIDE, CLICK!

| Weight approx. (lbs) | |

|---|---|

| Rail Slider for MSR Art. No. RN-RRS20 | 42 |

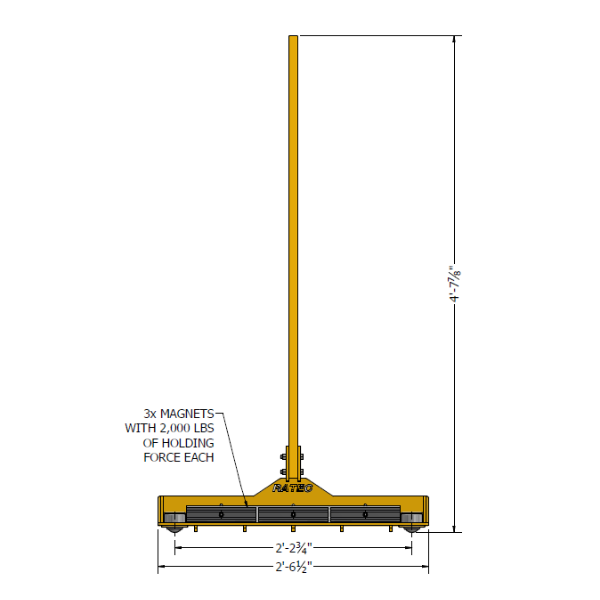

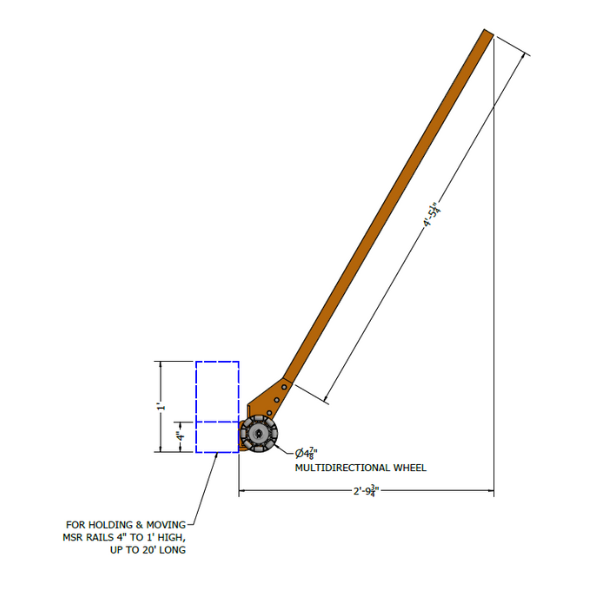

Multi Directional Rail Slider for MSR

RATEC Rail Slider for MSR's with Multidirectional Wheels A magnetic moving and handling device for your siderail system equipped with three magnets, each with 2000 lb. of holding force. Can hold & move magnetic rails from 4'' to 12'' height, and up to 20' long. No more bending or lifting. Easily slide your rail in place and click. POP, SLIDE, CLICK!

| Weight approx. (lbs) | |

|---|---|

| Multi Directional Rail Slider for MSR Art. No. 80272 | 40 |