Girder slabs and double walls, as well as thermal double walls, form a synthesis between prefabrication and on-site construction as so-called semi-prefabricated elements. The prefabricated elements are assembled on site using in-situ concrete. One of the greatest advantages of the double wall is the formwork-smooth surface quality on both sides.

Girder slabs can be produced either stationary on casting / tilting tables or in a pallet circulation system. Double walls are traditionally produced in circulation.

The plant equipment for girder slab and double wall plants is constantly being further developed and is today already characterised by a very high degree of automation. In the 1980s, Reymann Technik developed the first CAD/CAM-controlled circulation system for the production of these elements. Today, automated formwork and reinforcement processes are state-of-the-art, when equipping new production plants. The entire production process is controlled by software and supplemented by modern workstations in the factory where the employees have an overview of the entire production process.

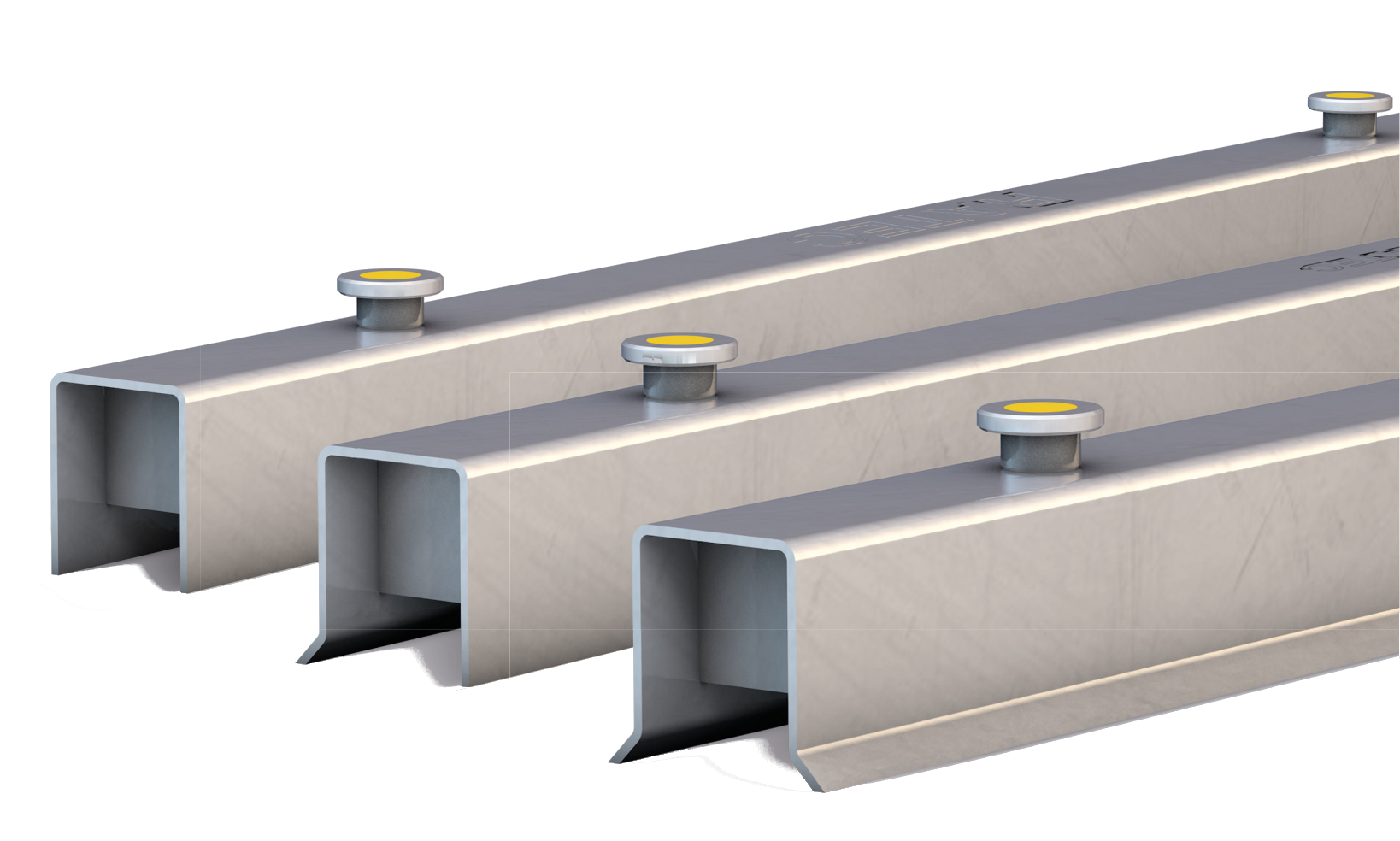

The according formwork solutions have also continuously adapted to the increasing degree of automation. Our RT U60 Pro formwork system is specially designed for girder slab and double wall production. The shuttering can be configured for common formwork robots and is available in lengths from 450 - 3980 mm.

Learn more about RT U60 Pro